|

01、

Graphite electrode should be covered with rain-proof tarpaulin in the process of transportation.

|

02、

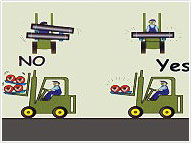

Be careful when transporting and pilling electrode with forklift and avoid of Collision. One layer of goods at a time; notice the balance and alignment and avoid falling or breakage.

|

03、

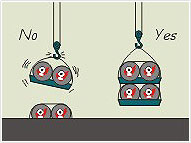

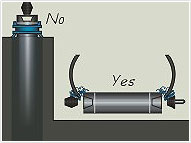

When loading and unloading with forklift, wire rope must be used and steel wrapping tape cannot be employed directly to fetch electrode.

|

|

04、

Electrode should be stored in clean and dry place. When pilling up outdoors, it should be covered with rain-proof tarpaulin and the number of pilling layers ought not to exceed four.

|

05、

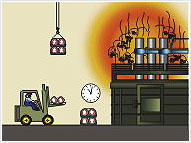

Electrode should be placed and dried beside the electric furnace in advance before using. The temperature should not exceed 150℃ and the time should not be less than 24 hours

|

06、

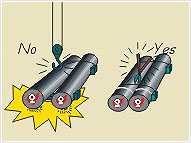

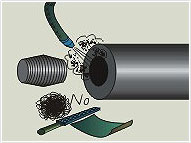

When using electrode, special tools should be employed to cut the steel wrapping tape, and crane should not be adopted to avoid bursting.

|

|

07、

Before connecting, clean the thread of electrode first and screw the joint to the end of electrode, and hoist joint to other end. Don't touch the thread, and don't put the joint directly into the working electrode on furnace.

|

08、

Steel-wire ball, metallic brush or emery cloth is not allowed for cleaning electrode thread, but compressed air free of oil and water is available.

|

09、

Use revolved resilient hanger and put soft truss pad under the electrode joint to avoid breakage of thread.

|

|

10、

Before connecting, clean the screw thread of electrode with compressed air free of oil and water.

|

11、

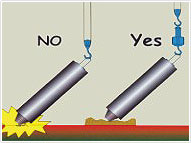

Lift the electrode to furnace by using hoister with resilient hanger, and find out the center and move slowly downwards, screw and tight with hoop.

|

12、

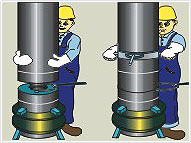

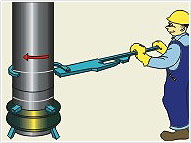

Use special caliper to tight electrode according to rated torque by mechanical way, hydraulic pressure or wind pressure equipments should also be available.

|

|

13、

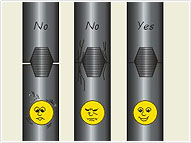

If the two poles of electrode are untouched or touched in overpressure, this may cause bad effect. Please refer to the rated torque in the right form.

|

Dia

|

Torque

|

Dia

|

Torque

|

|

Inch

|

Mm

|

Kg/m

|

Inch

|

Mm

|

Kg/m

|

|

8

|

200

|

35

|

16

|

400

|

110

|

|

10

|

250

|

50

|

18

|

450

|

160

|

|

12

|

300

|

70

|

20

|

500

|

210

|

|

14

|

350

|

90

|

24

|

600

|

350

|

|

14、

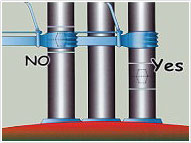

Electrode clamp holder must be placed between the two white guard lines. Clamp holder and interfaces of the electrode must be cleaned regularly to keep good touch with electrode. Cooling water jacket of the clamp holder should be tight to prevent water leakage.

|

15、

To avoid the electrode breakage, insulating materials should not be put into the furnace. The working current of electrode must be conformity with the allowable current of electrode in the instructions.

|

|

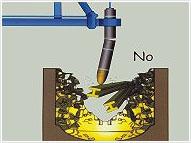

16、

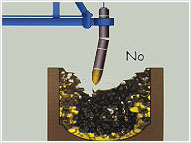

In order to avoid electrode breakage , put the large materials in lower part and small materials in the upper part.

|